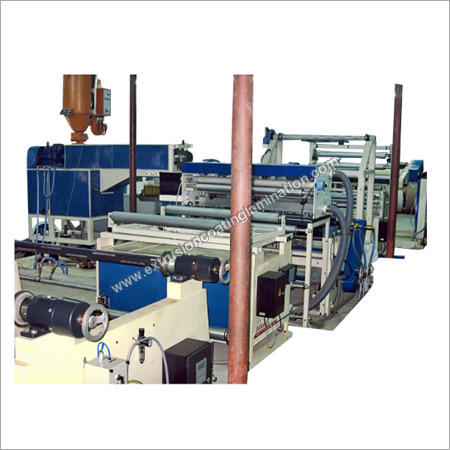

Flat Fabric Extrusion Coating Lamination Plant

Flat Fabric Extrusion Coating Lamination Plant Specification

- Type

- Flat Fabric Extrusion Coating Lamination Plant

- Material

- Steel

- Capacity

- 120 Kg/Hr Kg

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- Frequency Speed Control

- Drive Type

- Electric

- Screw Diameter

- 75 mm Meter (m)

- Power

- 16-20 kW Watt (w)

- Color

- Multicolor

- Warranty

- 1 Year

Flat Fabric Extrusion Coating Lamination Plant Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Gujrat

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 2 Pieces Per Month

- Delivery Time

- 2-3 Months

- Main Export Market(s)

- Western Europe, Asia, Australia, Eastern Europe, Middle East, Africa, South America, Central America, North America

- Main Domestic Market

- All India

About Flat Fabric Extrusion Coating Lamination Plant

Since inception year, we have been affianced to manufacture and supply Flat Fabric Extrusion Coating Lamination Plant. The provided plant is suitable for the repetitive lamination of different materials that are used to pack foods, cosmetics, and pharmaceutical products. Manufactured by our adept professionals using superior-quality components and progressive techniques, this plant is also tested on defined quality parameters to ensure its flawlessness. Besides this, we offer this Flat Fabric Extrusion Coating Lamination Plant to the clients at marginal prices.

Features:

-

High operational fluency

-

Low maintenance

-

Energy efficient

-

Easy to operate

High Performance and Reliability

Built with a focus on robustness and precision, this extrusion coating lamination plant integrates a 75 mm screw and advanced frequency speed control to ensure consistent quality and enhanced productivity. The fully automatic and computerized system enables seamless operation, reducing manual intervention and optimizing process efficiency.

Versatile Coating and Lamination

Suitable for a wide range of flat fabrics, this plant delivers excellent adhesion and uniform lamination. The steel construction ensures longevity, while the customizable speed settings allow manufacturers to adapt the process for various materials and end-product specifications.

Committed to Quality and Service

Manufactured in India with a strong emphasis on export standards, the plant comes with a 1-year warranty, providing assurance of reliability and dedicated post-sale support. Its electric drive and modern control systems meet the needs of both domestic and international fabric processing industries.

FAQ's of Flat Fabric Extrusion Coating Lamination Plant:

Q: How does the Flat Fabric Extrusion Coating Lamination Plant operate?

A: The plant utilizes an automatic, computerized control system with electric drive and frequency speed control, allowing epoxy or polymer coatings to be extruded and uniformly laminated onto flat fabric. Operators monitor and adjust parameters digitally, ensuring precision and consistent quality throughout the process.Q: What types of materials can be processed using this lamination plant?

A: This machine is designed for coating and laminating various flat fabrics, including woven and non-woven substrates. Its robust steel build and adjustable speed allow it to handle diverse materials across multiple industrial applications.Q: When is it recommended to use this extrusion coating lamination plant?

A: The plant is ideal for use when high-volume, consistent, and high-quality lamination is required, particularly in textile, packaging, and industrial production settings that demand efficiency and reliability for large-scale output.Q: Where is the Flat Fabric Extrusion Coating Lamination Plant manufactured and exported from?

A: The plant is manufactured in India by experienced manufacturers who also handle international exports, supporting customers globally with reliable machinery and after-sales service.Q: What is the process flow of extrusion coating and lamination in this plant?

A: Fabric is fed through the machine where a polymer resin is melted and extruded onto its surface. The materials are then pressed together using precision rollers, cooled, and finally collected as a uniformly laminated product.Q: How should operators use the computerized control system?

A: Operators interact with an intuitive digital panel to set process parameters such as temperature, speed, and pressure. The system features real-time monitoring and diagnostics to facilitate smooth operation and timely adjustments.Q: What are the main benefits of using this automatic lamination plant?

A: Major advantages include high production capacity, reduced manual labor, consistent product quality, adaptable processing speeds, and the assurance of a 1-year warranty, making it a cost-effective solution for large manufacturers and exporters.

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 2 Pieces Per Month

- Delivery Time

- 2-3 Months

- Main Domestic Market

- All India

- Main Export Market(s)

- Western Europe, Asia, Australia, Eastern Europe, Middle East, Africa, South America, Central America, North America

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Extrusion Coating Lamination Plant Category

Extrusion Coating Machine

Minimum Order Quantity : 1 Piece

Type : Extrusion Coating Machine

Computerized : Yes

Drive Type : Electric, Other

Warranty : 1 Year

Control System : Frequency Speed Control

Extrusion Coating Lamination

Minimum Order Quantity : 1 Piece

Type : Extrusion Coating Lamination

Computerized : Yes

Drive Type : Other, Electric

Warranty : 1 Year

Control System : Frequency Speed Control

Coating Lamination Plant

Minimum Order Quantity : 1 Piece

Type : Coating Lamination Plant

Computerized : Yes

Drive Type : Other, Electric

Warranty : 1 Year

Control System : Frequency Speed Control

Extrusion Coating Lamination Machine

Minimum Order Quantity : 1 Piece

Type : Extrusion Coating Lamination Machine

Computerized : Yes

Drive Type : Other, Electric

Warranty : 1 Year

Control System : Frequency Speed Control