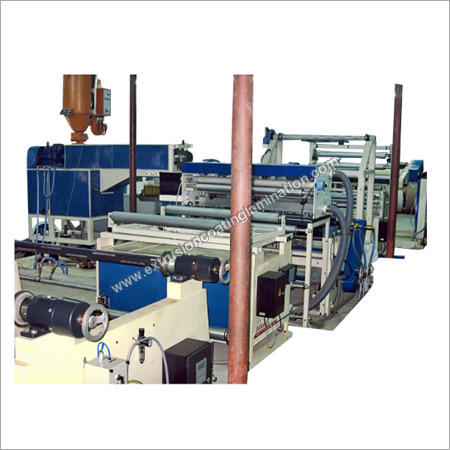

T Die Extrusion Coating Lamination Extruder Plant

T Die Extrusion Coating Lamination Extruder Plant Specification

- Type

- T Die Extrusion Coating Lamination Extruder Plant

- Material

- Steel

- Capacity

- 120 Kg/Hr Kg

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- Frequency Speed Control

- Drive Type

- Electric

- Screw Diameter

- 75 mm Meter (m)

- Power

- 16-20 kW Watt (w)

- Color

- Multicolor

- Warranty

- 1 Year

T Die Extrusion Coating Lamination Extruder Plant Trade Information

- Minimum Order Quantity

- 1 , , Piece

- FOB Port

- Gujrat

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 2 Pieces Per Month

- Delivery Time

- 2-3 Months

- Main Export Market(s)

- Western Europe, Asia, Australia, Eastern Europe, Middle East, Africa, South America, Central America, North America

- Main Domestic Market

- All India

About T Die Extrusion Coating Lamination Extruder Plant

The offered T Die Extrusion Coating Lamination Extruder Plant has gained huge demands across the nation due to its unmatched features. This extruder plant is ideal to produce the slim lining layers of polymers to extrude over the woven sacks, bags, foils and other packaging materials. This plant is designed and assembled by our adept professionals using optimal quality components and modern techniques at our technically-sound production unit. Further, we offer this T Die Extrusion Coating Lamination Extruder Plant to the clients at marginal prices.

Features:

-

Optimum performance

-

Longer service life

-

Lower power consumption

-

Less maintenance

Advanced Automation for High Productivity

This extruder plant is designed for automated performance, leveraging computerized controls and frequency speed regulation. Operators benefit from reduced manual intervention and enhanced accuracy, ensuring consistent output and minimal downtime during high-volume production.

Durable Construction and Efficient Design

Made from heavy-duty steel, the machine is built for longevity and sustained operation in demanding industrial environments. Its optimized screw diameter and electric drive system contribute to reliable, efficient energy usage, supporting both operational excellence and long-term savings.

FAQ's of T Die Extrusion Coating Lamination Extruder Plant:

Q: How does the T Die Extrusion Coating Lamination Extruder Plant operate?

A: This machine utilizes an electric drive and computerized automatic controls to manage the lamination and coating process. It relies on a frequency speed control system to regulate operation, ensuring precision and consistent product quality.Q: What materials and specifications define this extruder plant?

A: The plant is made from durable steel and features a 75 mm screw diameter. It operates at a power range of 16-20 kW, with a multicolor finish, and can process up to 120 Kg of material per hour. The type is specified as T Die Extrusion Coating Lamination, equipped with automatic and computerized functions.Q: When is the ideal time for maintenance on this machinery?

A: Regular maintenance is recommended at intervals specified in the user manual, typically after every production cycle or as indicated by the control system alerts. Scheduled maintenance helps maintain peak machine efficiency and prolong lifespan.Q: Where is this extruder plant manufactured and exported from?

A: This plant is manufactured in India by an experienced exporter and manufacturer, with global export capabilities to various international markets.Q: What is the process for coating and lamination using the plant?

A: The process involves feeding base material into the extruder, which then melts and coats the substrate through a T die, resulting in laminated or coated sheets. The frequency speed control system ensures precise process adaptability for different materials.Q: How can users benefit from the frequency speed control system?

A: The frequency speed control allows users to adjust operation speed for different materials and thickness requirements, improving process flexibility while enhancing energy efficiency and reducing operational costs.Q: What is the warranty coverage for this extruder plant?

A: The product comes with a 1-year warranty covering manufacturing defects and system malfunctions, with support provided by the manufacturer in India.

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 2 Pieces Per Month

- Delivery Time

- 2-3 Months

- Main Domestic Market

- All India

- Main Export Market(s)

- Western Europe, Asia, Australia, Eastern Europe, Middle East, Africa, South America, Central America, North America

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Extrusion Coating Lamination Plant Category

Bopp Double Side Extrusion Coating Machine

Minimum Order Quantity : 1 , , Piece

Color : Multicolor

Control System : Frequency Speed Control

Power : 1620 kW Watt (w)

Screw Diameter : 75 mm Meter (m)

Material : Steel

Extrusion Coating Lamination Plant

Minimum Order Quantity : 1 Piece

Color : Multicolor

Control System : Frequency Speed Control

Power : 1620 kW Watt (w)

Screw Diameter : 75 mm Meter (m)

Material : Steel

Extrusion Coating Lamination Machine

Minimum Order Quantity : 1 Piece

Color : Multicolor

Control System : Frequency Speed Control

Power : 1620 kW Watt (w)

Screw Diameter : 75 mm Meter (m)

Material : Steel

Extrusion Laminating Machine

Minimum Order Quantity : 1 Piece

Color : Multicolor

Control System : Frequency Speed Control

Power : 1620 kW Watt (w)

Screw Diameter : 75 mm Meter (m)

Material : Steel