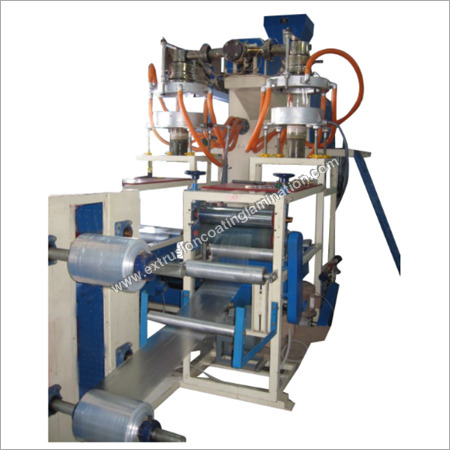

Pp Tq Film Plant

Pp Tq Film Plant Specification

- Type

- Pp Tq Film Plant

- Material

- Steel

- Capacity

- 120 Kg/Hr Kg

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- Frequency Speed Control

- Drive Type

- Electric

- Screw Diameter

- 75 mm Meter (m)

- Power

- 16-20 kW Watt (w)

- Color

- Multicolor

- Warranty

- 1 Year

Pp Tq Film Plant Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- Gujrat

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 2 Pieces Per Month

- Delivery Time

- 2-3 Months

- Main Export Market(s)

- Australia, Western Europe, Middle East, Central America, Africa, South America, Asia, Eastern Europe, North America

- Main Domestic Market

- All India

About Pp Tq Film Plant

Fostered with sound industry knowledge, we have been able to manufacture and supply our clients a premium range of PPTQ Film Plant. The offered product is precisely engineered using high quality raw material in sync with international quality standards. This PPTQ Film Plant is available in different capacities as per the specific needs of clients. Raw materials used for the fabrication are sourced from the reliable and trusted vendors of the industry.

Features

- Different application for Packing

- Nitrided Screw and Barrel made out from special nitro alloy steel for long life.

- Helical Gear Box with inbuilt Thrust Bearing.

- Specially designed spiral type die

- PID Temperature Controller.

- AC Motor Synchronization.

|

MODEL |

JEC-2650 |

JEC-2650 |

JEC-2765 |

|

Screw Diameter |

50 mm |

50 mm |

65 mm |

|

Extruder Drive |

11 KW |

11 KW |

11 KW |

|

L/D Ratio |

30:1 |

30:1 |

30:1 |

|

Max Output(Kg/hr) |

40-45 |

40-45 |

70-80 |

|

Lay flat Width |

26" |

15" |

30" |

|

Thickness Range (Ga. |

80-300 |

80-300 |

80-300 |

|

Dies (Spiral Type) mm |

100 & 200 |

175 (2 Nos.) |

125, 200, 300 |

|

Nip Roll Size |

30" |

18" x 2 |

36" |

|

Nip Roll Drive |

0.37 KW |

0.55 KW x 2 |

1.5 KW |

|

Winder Width |

26" |

18" x 2 |

36" |

|

Connected Load |

26 KW |

38 KW |

40 KW |

|

Overall Dimensions(ft.) |

18' L x 8' W x 12' H |

20' L x 8' W x 12' H |

20' L x 8' W x 13' H |

Advanced Automation for Efficient Film Production

The PP TQ Film Plant is engineered for streamlined and consistent operation. Its automatic grade and computerized control system enable precise control over production parameters, minimizing human error and maximizing output. Designed with efficiency in mind, users can count on rapid processing of up to 120 kg/hr, thanks to its robust hardware and electric drive system.

Durable Design and Multicolor Compatibility

Constructed from high-grade steel, the plant ensures durability and long service life even under continuous operation. The multicolor feature allows manufacturers to produce films in a variety of colors, catering to diverse market demands. Combined with a 1-year warranty and solid engineering, users experience reliable performance and minimal downtime.

FAQ's of Pp Tq Film Plant:

Q: How does the frequency speed control system benefit plant operation?

A: The frequency speed control system enables operators to precisely adjust the speed of the machinery, ensuring optimal film thickness and quality. This feature enhances energy efficiency and improves product consistency during production.Q: What materials can be processed with the PP TQ Film Plant?

A: The PP TQ Film Plant is specifically designed to process polypropylene (PP) materials, allowing the production of high-quality PP films in various colors as required by different applications.Q: When is regular maintenance required for optimal performance?

A: Regular maintenance is suggested at intervals recommended in the user manual, typically every six months, to ensure sustained performance, reduce wear, and avoid unplanned downtime. The plant's steel construction helps minimize maintenance needs.Q: Where is the PP TQ Film Plant manufactured and exported from?

A: This plant is manufactured and exported from India by a reputable manufacturer and exporter, ensuring compliance with international quality standards and reliable post-sale support.Q: What is the process involved in producing PP films using this plant?

A: The process begins with feeding PP material into the plant, which is then melted and extruded using a 75 mm screw. The computerized system controls temperature and speed, forming thin films that pass through cooling and winding stages for finishing.Q: How can an automatic and computerized control system improve usage?

A: The automatic and computerized control system simplifies plant operation, allowing for easy monitoring and adjustment of parameters. This ensures consistent film quality, reduces manual intervention, and enables more efficient production cycles.Q: What are the main benefits of using this plant for large-scale PP film manufacturing?

A: Major benefits include high production capacity (up to 120 kg/hr), reliable multicolor film output, reduced operational costs due to automation, and robust durability backed by a one-year warranty. These factors make it ideal for industrial-scale usage.

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 2 Pieces Per Month

- Delivery Time

- 2-3 Months

- Main Domestic Market

- All India

- Main Export Market(s)

- Australia, Western Europe, Middle East, Central America, Africa, South America, Asia, Eastern Europe, North America

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+